Hoist & Crane Service Group offers advanced, real-time data collection via advanced sensory systems, easily retrofitted to any manufacturers' lifting equipment. HALO SmartCrane streams real-time data from your equipment providing critical safety alerts, enables behavior based safety programs for your operators, and creates the data information framework to allow adoption of cutting edge condition based maintenance programs—knowing exactly where your friction components, such as contactors and load brakes, are in their expected lifespan.

HALO SmartCrane Program Features:

- Data is collected and can be communicated in real time.

- Install a condition-based maintenance program by knowing exactly where your friction components, such as contactors and load brakes are in their expected lifespan.

- Critical safety conditions, such as side loads and overloads, can be detected and averted.

- Improve your operators by setting restrictions and monitoring performance through Operator Authentication.

- Using proximity sensors, collect data on product weight and movement throughout your facility.

HALO SmartCrane Service Overview

Every new customer engagement starts with an Equipment Life Cycle Assessment. Once the lifecycle survey is complete, the HALO SmartCrane unit’s data logger is updated, installed, and calibrated on your crane.

Based on confidence factors gleaned from the lifecycle survey, we project the remaining life cycle on all equipment. We zero-set the new life cycle once we replace a piece of equipment. The longer you use the HALO service, the more accurate the service cycle and equipment end-of-life data become. With this increased accuracy, you can budget more accurately because of lead times. You can also initiate Condition-Based Maintenance, which is analogous to just-in-time delivery in the product production world.

Your HALO system can be configured to alert Hoist & Crane directly when an issue is detected, a life cycle service event approaches, or the system can alert you, and you can initiate the service call.

As a HALO customer, you'll receive a smartphone app that shows real-time data and reporting right on your phone—for all equipment including hoist, trolley, bridge, and wire rope.

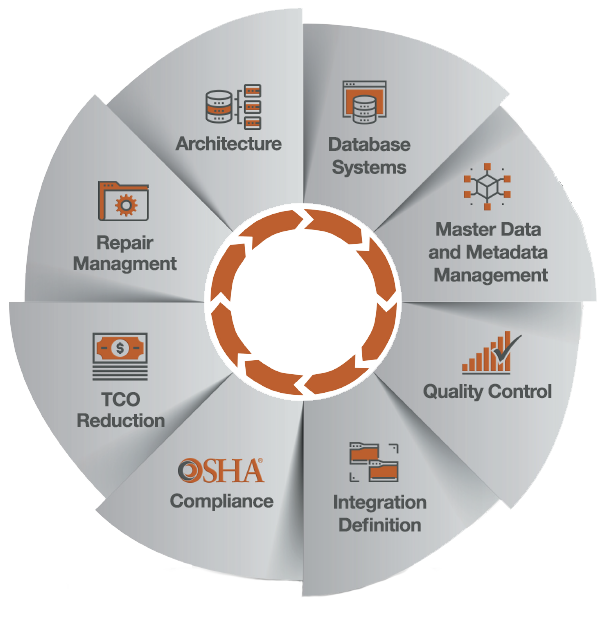

HALO SmartCrane Data Management

Hoist & Crane Service Group’s exclusive HALO SmartCrane Data Management Program is the most effective way for you to manage critical inspection data. As a core competency service provider, one of our primary focuses is generating and presenting inspection data accurately and efficiently. Discrepancies and other pertinent data found during the inspection are offered in a way that can be easily filtered, prioritized, and managed.

- Display all your inspection data in one, easy-to-review format.

- Sort inspection discrepancies by equipment type, location, priority, etc.

- Manage Repairs with an attached budgetary planner.

- Data tables are accessible in Microsoft Excel, eliminating the need for additional expensive proprietary software.

HALO SmartCrane Engineered Services

Often clients experience repeated equipment failures due to operating their equipment outside of manufacturer-suggested parameters or misaligning equipment to jobs. In other instances, there are industry-level issues like Tip Loading, Side Loading, and Overloading that customers wrongly assume are just part of life.

In those instances, Hoist & Crane's Engineered Services can provide customized one-off solutions to address and overcome the issue. Believing that the solution can't cost more than the problem, Hoist & Crane's experienced staff of industry veterans create economically mindful solutions that save our customers

A few of the companies that have trusted us with their machinery.