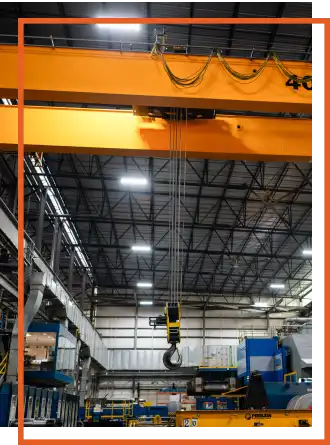

Primary Metal Lifting Repair Solutions

Where Heavy Loads Meet Precision

Primary metals facilities operate in some of the most demanding industrial environments. Extreme heat, pervasive dust, corrosive atmospheres, and continuous heavy-duty cycles push lifting equipment to its limits every single day.

We specialize in the unique challenges of steel mills, foundries, and metals processing facilities. Our inspection, maintenance, and modernization services ensure your equipment performs reliably in conditions that would overwhelm standard industrial cranes.

Specialized Services Across Primary Metals Facilities

Moving massive loads of raw materials, handling molten metal, and operating in high-heat environments requires equipment built—and maintained—differently. Our technicians bring specialized training and hands-on experience in primary metals operations, understanding both the equipment demands and the safety standards critical to your industry.

We provide comprehensive support for:

Customized Maintenance and Modernization for Maximum Uptime

Standard maintenance schedules don’t work in primary metals. Our Protective Maintenance Control Program schedules service based on your specific operational demands, duty cycles, and equipment conditions.

When modernization is needed, we upgrade your systems with enhanced controls, improved safety features, and technology designed for high-heat, heavy-duty environments—delivering turnkey solutions built for the rigors of metals production.

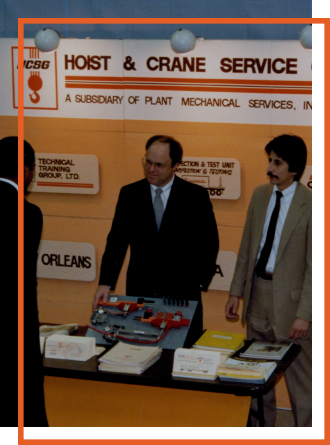

With Hoist & Crane Service Group, your lifting equipment stays performing safely and reliably in the toughest conditions.