Automotive Lifting Repair Solutions

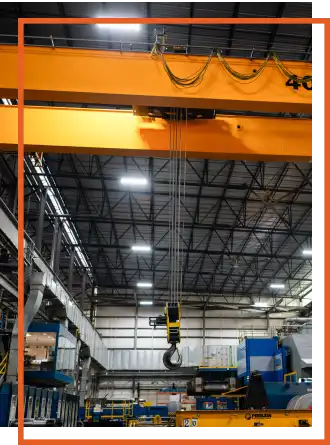

Precision Performance for Production

In automotive manufacturing, every second counts. Just-in-time production schedules, tight tolerances, and continuous operations demand lifting equipment that performs flawlessly—shift after shift, day after day.

From automated production line material handlers to overhead maintenance cranes, we deliver inspection, maintenance, and modernization services designed specifically for the speed and precision requirements of today’s automotive plants. Our goal is simple: keep your equipment running so your lines never stop.

Upgrades That Drive Performance

We understand the unique pressures of high-speed automotive production, where downtime costs thousands per minute. Our preventive maintenance strategies and rapid response capabilities ensure your lifting systems operate reliably around the clock.

We provide comprehensive support for:

Smart Maintenance and Modernization for Competitive Operations

The automotive industry evolves constantly—new models, new processes, new production demands. Your equipment must keep pace while maintaining the precision required for moving body panels, powertrains, and critical assemblies.

Our BeamMaster maintenance and fatigue management program monitors actual equipment usage and component wear in real time, providing predictive maintenance alerts before failures occur. This reduces total cost of ownership, extends equipment life, and eliminates unplanned downtime that disrupts production schedules.

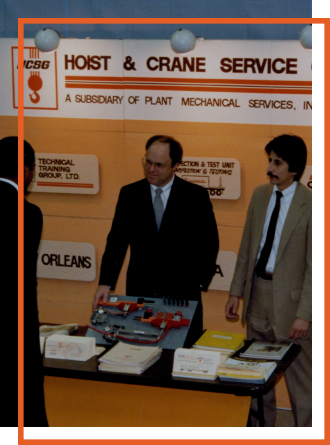

With Hoist & Crane, you gain a partner committed to keeping your automotive operations moving efficiently. Our comprehensive maintenance programs, modernization expertise, and emergency response capabilities help you meet production schedules, reduce costs, and maintain the competitive edge that defines success in automotive manufacturing.